Port Lands Flood Protection and Redevelopment

Location: Toronto, Ontario

Client: Cherubini Metal Works

Duration: 2019-2024

Key Staff: Robbie Fraser, Thomas McNutt, Marc Tarling, Todd Menzies

Awards:

Project Description

Waterfront Toronto undertook a major project by creating a naturalized river valley for the mouth of the Don River. In doing so, they reclaimed an industrial zone for mixed-use development and the construction of significant park and green space. The new Don River channel, updated road and light rail required the construction of four new bridges. Two of the new bridges that crossed the Keating Channel were to replace the previous Cherry St North Bridge. The other new bridges on Cherry St and Commissioners Street were set to cross the new river valley.

Aerial footage of the transportation and erection of the Cherry Street North bridge during the Waterfront Toronto Redevelopment Project.

Harbourside was retained to provide Erection and Fabrication Engineering and Quality Verification Engineering services. This was for the fabrication, transportation and erection of the steel arch Port Lands bridges.

Harbourside’s Role

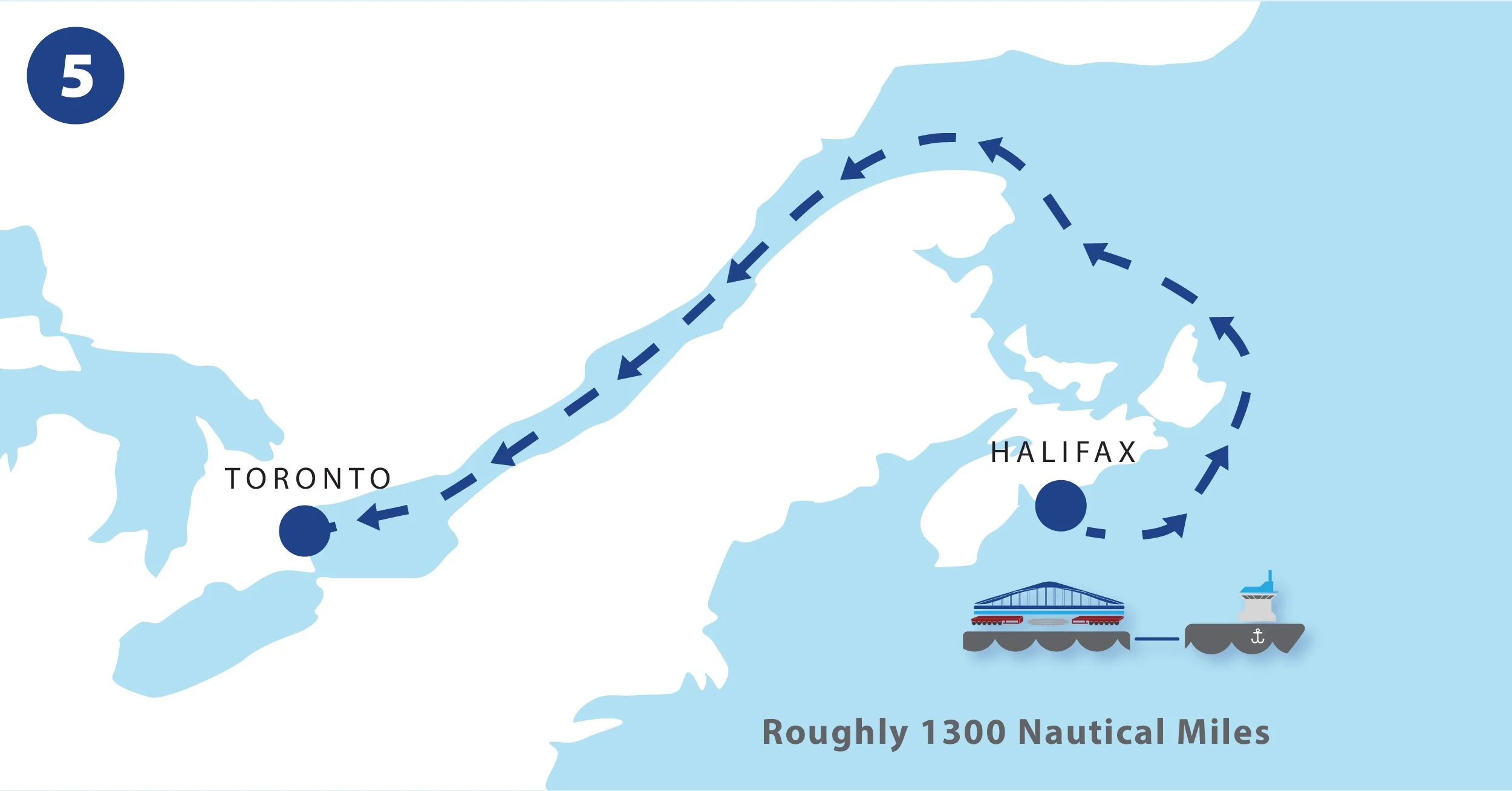

Harbourside was retained by Cherubini Metal Works to provide erection engineering services for the fabrication, transportation and erection of the four steel arch bridges. It was determined at the start of the project that the most economical means for fabricating and erecting each of the bridges was to complete as much of the work and coatings work as possible in the fabrication shop. This would provide the high-quality fabrication and paint finish that was required right here in Halifax. It would also enable the team to use accelerated bridge construction techniques (ABC) to minimize the fabrication, assembly, and coatings work done on site.

To meet this requirement, ABC erection and transportation methodologies were developed for each of the bridges. This allowed the fabricator to complete almost all steel fabrication and assembly of the bridge superstructures in the fabrication shop in Halifax.

Fabrication

During fabrication Harbourside provided the fabricator with geometry control procedures and designed temporary works that were required during the assembly of the Port Lands bridge superstructures. Harbourside also coordinated with multiple Self Propelled Modular Transporter (SPMT) suppliers for moving the bridges from the fabrication shop to the coatings tent, onto the barge for transport to Toronto. Harbourside also coordinated the unloading of the bridge superstructures in Toronto.

Transportation and Erection.

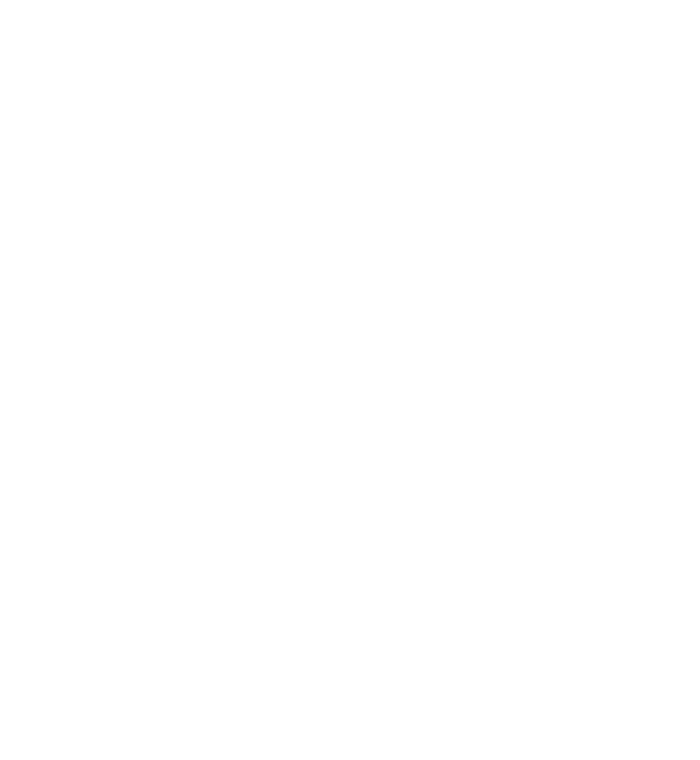

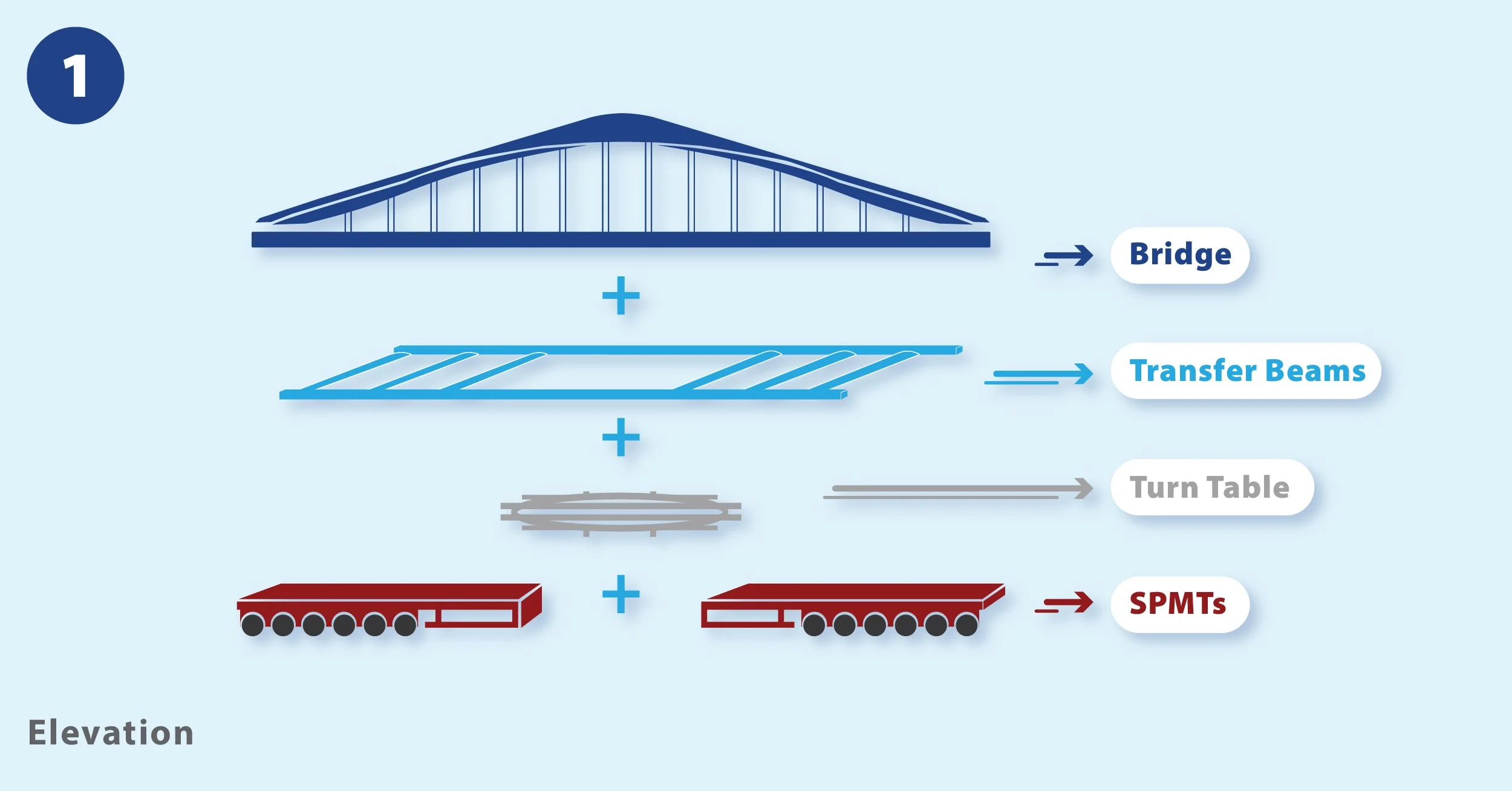

For the new 56-meter Cherry Street Bridges that cross the Keating Channel (one vehicular and one light rail bridge), the bridge superstructures were loaded onto large girders and a turntable. This in turn was mounted to the barge deck in Dartmouth. Once the barge arrived in Toronto, the bridge was rotated 90 degrees so that it was perpendicular to the barge. Once rotated, the bridge was moved into position above the abutments. The barge was then ballasted down so that the bridge superstructures were supported by the new abutments.

Transportation Via Barge

The four-span Commissioner’s Street Bridge was transported to in two halves. Each of these was comprised of a 56-meter main span, and a 20-meter approach span. The halves were loaded onto the barge using SPMTs in Dartmouth and secured for transit to Toronto. Upon arrival, they were unloaded using SPMTs and driven along a temporary engineered haul route to the newly built abutments. Once both halves of the bridge were in Toronto, they were aligned, and the center splice was welded together. This created a single continuous superstructure.

For each of the bridges, Harbourside completed the full erection phasing, and designed all temporary works for the fabrication, transport and erection stages of construction. This included SPMT blocking, sea lashing, jump bridges and abutments for loading and unloading the barge. It also included the bespoke turntables and transfer beams.

Additionally, Harbourside provided Quality Verification Engineering services for the fabrication and erection of all four of the steel-arch Port Lands bridges.

Harbourside also provided geotechnical design services for the offload haul routes and temporary construction and staging areas. The haul route design required the use of geo-grid to provide a stable driving surface in the constrained site. The area bordered the edge of the property and an active excavation.

Unique Challenges

The engineering required to transport the fully fabricated steel bridge superstructures by barge and erect on the permanent bearings was a significant undertaking. As a reminder, the overall goal in transporting the ships by barge was to decrease the amount of field work necessary. All the temporary works had to be designed for each bridge during each stage. Full phasing documents had to be developed, and the integrity of the bridge superstructure had to be maintained during all conditions for the stability of the structure.

Despite their cohesive look, transportation methodologies had to be adapted to meet the individual needs of each of the bridge. These took into consideration the offloading and erection constraints once the barges arrived at their destination. Strict geometric, elevation, and thermal controls were required during all phases of construction. Even minor decisions in the shop could adversely affect activities during erection and vice versa.

The three span Cherry Street South bridge structure was too long to ship fully assembled on the barge. Because of this, the approach spans were temporarily suspended from below the main span during transit. The bridge superstructure was dynamically offloaded using SPMTs in Toronto, while the approach spans were strategically lowered into the proper position. These flanked the main arch span, and all three spans were supported on temporary blocking and footings. This was so that the approach spans could be welded on each end of the main arch span. The fully welded superstructure was then moved into position over the permanent piers and abutments using SPMTs. Finally, the bridge superstructure was placed on the permanent bearings.

Social Impact

The Port Lands Bridges showcase Nova Scotia’s ability to export high-end engineering and construction services on an international level. Awarded to local Nova Scotian firms after an international competitive tender period, the project was completed on time and on budget.

By maximizing the amount of work that was completed in the fabrication shop, most of the work to build and coat these structures was completed in Nova Scotia. Traditional erection methodologies would have required much more of the work to be done on-site in Toronto. The innovative transportation and erection techniques used on this project were critical in the project being awarded to a local fabricator. This maximized the amount of work and economic benefit to the province of Nova Scotia.

It also highlighted the fact that engineering and construction firms like Harbourside and Cherubini are fighting the ‘brain drain’ epidemic plaguing the Maritimes. Harbourside takes great pride in reversing the ‘brain drain’ tide. We do this by allowing local engineers to continue to work on world-class projects from their home province. This has fostered an environment and reputation where out-of-market bridge owners have sought out Nova Scotian engineering services specifically. The brightest engineers from other parts of Canada and the world want to advance their careers right here in Nova Scotia.

Environment

Mitigating environmental impacts was a key consideration of Waterfront Toronto’s undertaking to transform Toronto’s Port Lands. Portions of this industrial area were at risk of flooding and the soil was contaminated.

As one of the largest waterfront revitalizations in the world, it included a naturalized river valley for the mouth of the Don River, a reclaimed industrial zone for mixed-use development, and the creation of sprawling parks and green spaces. The four newly constructed signature bridges were part of the overall vision to connect downtown Toronto to Ookwemin Minising (formerly Villiers Island).

These bridges, and the accessibility they provide, are key components to the environmental impact of the revitalization project. With increased density and access to green spaces, urban carbon emissions drop dramatically. This would not be possible on Ookwemin Minising without the transit lanes and routing created through these bridges.

Harbourside took considerable care to ensure that its fabrication and loadout engineering designs would minimize impact to the environment. Shallow deposits of compressible organic silts posed a technical challenge to the short-term stability of the area. Completing detailed geotechnical analyses, Harbourside was able to determine safe slope offsets, and engineer fill extents and foundation designs for temporary works. Ultimately, Harbourside was able to tailor the haul-route design to satisfy the project constraints while optimizing material re-use. This was done while meeting the construction schedule, reducing costs to the client, and minimizing wastage of materials.